You may be familiar with the various colors associated with hydrogen, with green and blue hydrogen being well-known to the public, and newer colors like pink, yellow, or white emerging.

However, we won’t delve into these colors here, as it is already well explained elsewhere. Instead, let’s refocus on the hydrogen manufacturing process and how to bring this produced H₂ to the desired specifications.

The different colors of hydrogen are linked to specific manufacturing processes, each associated with a distinct environmental footprint indicated by its respective colors. Despite this, these colors suffer from a lack of clear definition. To address this ambiguity, we therefore recommend the use of “low-carbon hydrogen”.

According to the latest EU delegated acts, the condition for hydrogen to be considered low-carbon is when the emissions of the production life-cycle are less than 3.38 kg CO₂ e/kg H₂. This provides a standardized measure, offering clarity in categorizing hydrogen based on its environmental impact. It makes no doubt that low-carbon hydrogen will play a major role in the industry’s energy transition and the future of transportation. All of those promising applications require pure hydrogen and impurities removal is often seen as a black box when in reality there are a lot of technologies (and chemistry) behind.

Hydrogen can be produced by several manufacturing processes (steam methane reforming, gasification, water electrolysis) or can even be found underground. Naturally, depending on the manufacturing process, hydrogen will come together with an array of impurities: oxygen, water, carbon oxides and sulfur, just to name the major components.

Table 1 summarizes the different impurities observed depending on its manufacturing process.

On the consumer side of the value chain, different degrees of hydrogen purty are required, depending on its use. For direct uses in fuel cells (transportation / electricity genration), ultra-pure hydrogen is needed and the level well described in the ISO-14687-2019 norm. When hydrogen is used as a chemical reactant for fuel synthesis, other specifications may apply, depending on the technology, but usually involve sulfur and oxygen removal at least.

The first application is the PDU (Purification & Drying Unit) located directly downstream the electrolyzers. This purification package includes a deoxidizer to get rid of traces of O₂ and dehydrators to remove all traces of water.

Depending on the electrolysis technology (AEL / PEM) hydrogen comes out with different levels of oxygen, but always water saturated. Oxygen is easily reacted at low temperature with hydrogen over a precious metal catalyst: H₂ + ½ O₂ = H₂O.

.png?width=1470&height=609&name=MicrosoftTeams-image%20(2).png)

Axens has developed in its historic catalyst factory at Salindres, France, a very active palladium based catalyst, supported on a specific alumina.

As for the drying section, a zero hydrogen loss TSA (Temperature Swing Adsorption) loaded with Adsorbents ensures efficient water removal.

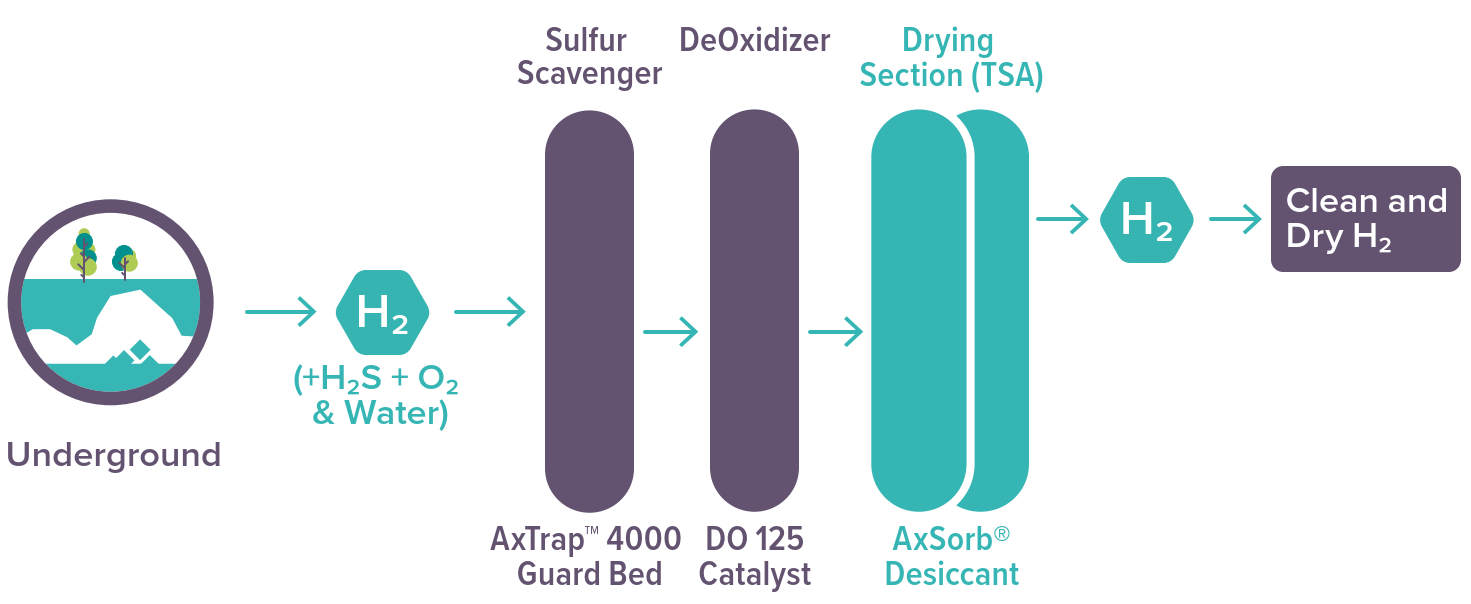

Underground storage is as of today the only way to store big quantities of hydrogen. Salt caverns are man-made cavities created in geological salt deposits, and where up to 6000 tons of H₂ can be stored at pressures as high as 200 bar. Field tests revealed that the withdrawn H₂ from those salt caverns were poisoned by H₂S (microbiological activity inside the cavern), oxygen and almost saturated with water.

A series of purification is therefore needed to clean this underground H₂:

Purification of hydrogen is at the cornerstone of the emerging hydrogen economy, linking any kind of manufacturing process to any kind of usage. Processing pure hydrogen in fuel cells or in catalytic reactors for further conversion is needed so that the units can run at maximum load without being poisoned by impurities.

Originating from years of experience in Adsorbents and Catalysts manufacturing, Axens proposes purification solutions on all kind of hydrogen streams so that any specification can be met.

Hydrogen is the base reactant (together with with CO₂) of other Axens processes such as Gasel (Alternative Fuels from Biomass, Waste & Gas), BioTfuel (Biomass to Lipids) for advanced fuels, or Jetanol (Alcohol to Jet) and LOHC.

Low Carbon Hydrogen Purification: Global Solution for Hydrogen Purification - Commercial Bulletin