As a market leader in the field of:

Axens offers a complete set of technologies and catalysts to meet the needs of refineries and provide high quality products complying with today’s most stringent clean fuel specifications.

A large Asian Oil company, with the ambition to become highly integrated by combining its petrochemical and refining activities, embarked in a mega project to supply its Purified Terephthalic Acid (PTA) plants with high purity paraxylene from its refinery side.

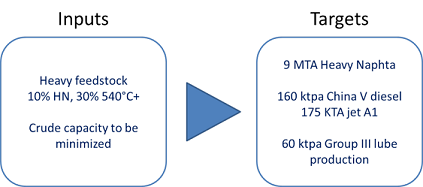

In addition to producing the world largest amount of high purity paraxylene, this “Crude-to-Paraxylene” (PX) complex with a processing crude capacity of 400,000 BPSD (barrels-per-day) will also produce a set quantity of final on-spec products such as gasoline and Group III lubes in order to meet local demand in clean fuels and lubes.

Among the various technologies available on the market, an H-OilRC® (ebullated-bed vacuum residue hydrocracking technology) followed by a Solvahl™ unit (Solvent DeAsphalting, SDA) was selected to convert the residue.

In the selected scheme, the naphtha, diesel, VGO and DAO produced from the conversion block are further upgraded in the new hydrocracking (HyK™) and hydroprocessing units to meet the final required product specifications.

Thanks to this configuration, 45% of Heavy Naphtha could be produced from the naphtha deprived crude to meet the paraxylene production objective as well as the clean fuels and lubes requirements.