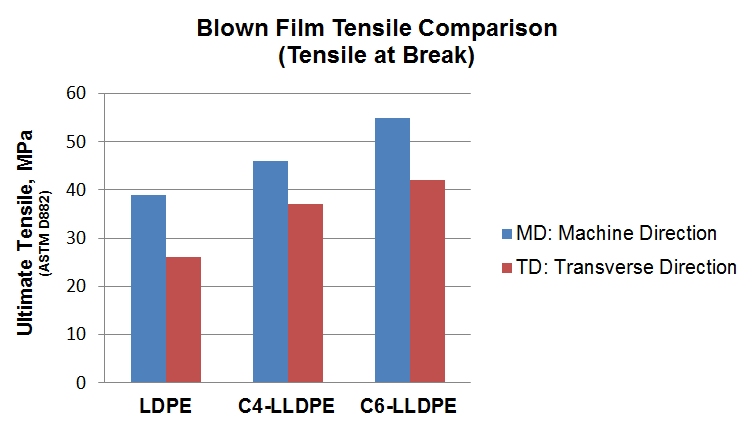

Mechanical resistance improvements of polyethylene with alpha-olefins addition

Axens offers world leading technologies to produce on-purpose high purity 1-Butene and 1-Hexene.

These technologies are based on homogenous catalysis for which extensive research and development has been performed since the mid-60’s and for which Yves Chauvin (from IFP Energies nouvelles) received the Nobel Prize in Chemistry in 2005.

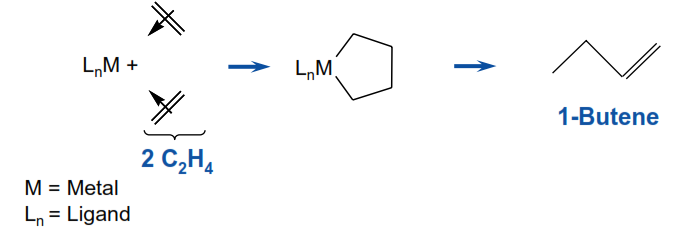

The advanced technical solution that represents AlphaButol is the result of a well-controlled isomer specific chemistry that leads to the selective formation of 1-Butene. The given mechanism and operating conditions provide AlphaButol with the great advantage of avoiding the formation of either isobutene or 2-Butene.

Selective ethylene dimerization mechanism

The technology employs a homogeneous catalysis system, which provides a steady operation at all times even when the feed quality fluctuates. It also exhibits a low CAPEX without the need for any compressors or superfractionation column. Lastly, 1-Butene’s high selectivity has been repeatedly demonstrated in commercial units.

These features are among the pillars that have built the technology’s success.

Over the last 5 years, several AlphaButol units have been successfully started-up. In addition, several projects have recently received awards and are at different stages, from design to currently starting-up. SOCAR joined the list of those who have chosen AlphaButol at the very end of 2016.

The AlphaButol units can be implemented via a modularized or stick-built approach.

An intermediate size skid mounted unit has already been started-up. This approach could advantageously fit other business cases where for instance secluded location or time to market considerations are among the key project decision-making elements.

AlphaHexol, a trimerization process based on the same principles and used to produce high quality 1-Hexene comonomer has also been marketed. Axens recently licensed a unit for a future large petrochemical complex.