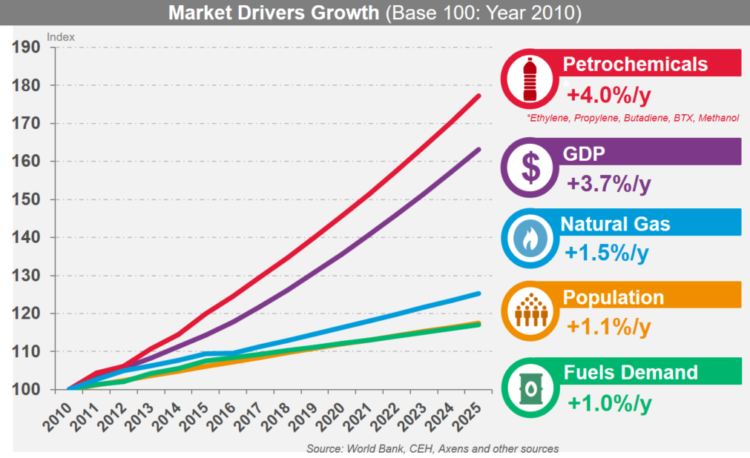

Based on various studies, a global trend shows that petrochemicals growth will exceed the one of transportation fuels. It is indeed expected to see a petrochemical global growth reaching 4% per year compared to about 1% for fuels.

In this context, implementing technologies to produce more valuable chemicals like aromatics is a strategic way for refiners and petrochemical players to drive future growth.

As a raw material in the polyester chain, mainly to manufacture fiber, film and polyethylene terephthalate (PET) bottle resins, paraxylene (PX) is a high-value component in the petrochemical sector and one of the most important xylene molecules.

Supported by recognized know-how and committed R&D efforts, a superior end-user oriented technical solution and a robust commercial experience are key promotion requirements of paraxylene and aromatics technologies.

With the ParamaX® Technology Suite, Axens is a leader in PX production and purification technologies. The ParamaX® Alliance gathers major actors of aromatics activity: Axens, ExxonMobil that is also a well-recognized operator and ThyssenKrupp Uhde.

The ParamaX® Technology Suite is a combination of top-of-the-line processes aiming at production of high purity PX and other aromatics molecules such as metaxylene, orthoxylene, benzene and/or toluene. The different process blocks composing the Paramax® Technology Suite are:

This integrated and optimized offer with a complete portfolio of leading-edge technologies has led Axens to be awarded for major projects all over the world.

Moreover, another key advantage is the Axens second generation energy-efficient ParamaX® Suite that delivers superior products yields while greatly reducing plant energy consumption and enabling to control investment for cost-advantaged aromatics production.

One of the latest major awards is the ParamaX® complex for aromatics production for SOCAR Turkey’s future site.