In the background of fuels demand shifting towards petrochemicals growth, Crude-To-Chemicals (CTC) projects are arising to manufacture in the same dynamics and with the expected flexibility level, the coveted high-value compounds (HVCs) and ever cleaner fuels, thus responding to global environmental preservation.

These new-generation projects fit into the context of the megatrends transforming the world of today and tomorrow. The CTC complexes deploy innovative technology routes making it possible to upgrade most of the Bottom-Of-the-Barrel therefore giving rise to the high added-value petrochemical intermediates, taking into account both client and market specificities.

The increasing trend for the main petrochemical intermediates compared to the one of the more tenuous fuel demand growth is driving the need for process flexibility to the expanding chemical value chain.

In response, new generation projects, CTC complexes, with their ultimate degree of integration between a refinery and a petrochemical plant, are designed for squeezing the Bottom-Of-The-Barrel to lift up the chemical yield.

Various mature and breakthrough technologies are combined to make the most of the Bottom-Of-the-Barrel, and this up to the targeted pure molecules, among which the ethylene, propylene and the paraxylene.

The interlinking between the three blocks; i.e.; conversion, olefins and aromatics, forming a CTC complex generates the synergy essential to maximal streams valorization.

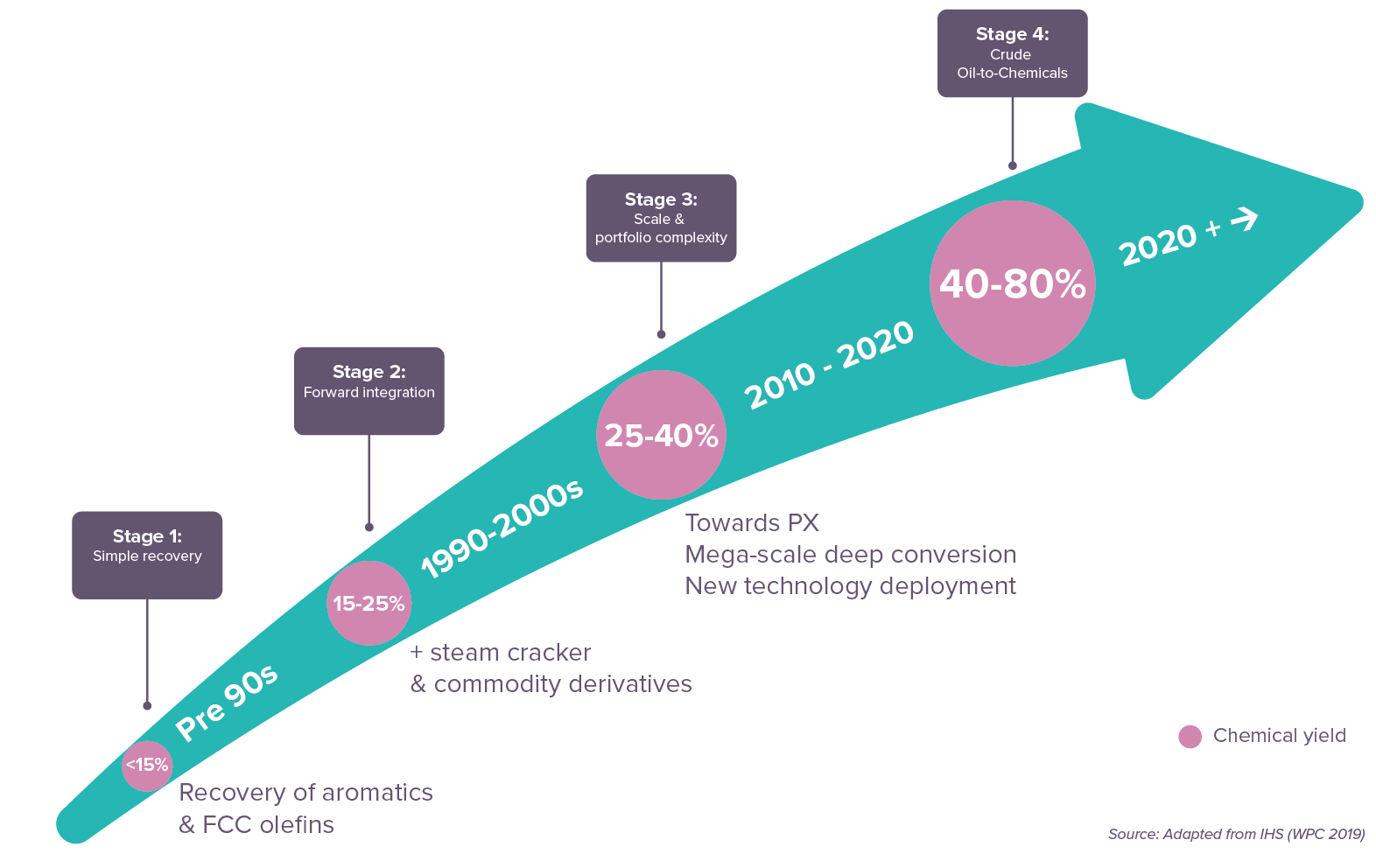

Throughout history, the refining industry has known how to adapt in order to meet the new challenges of global oil consumption patterns. The constant evolution of refining over time towards chemical yield was achieved in four main stages up to the ultimate integration degree between refining and petrochemicals materialized by the Crude-To-Chemicals (CTC) complexes corresponding to a chemical yield greater than 40%.

Combinations of mature and cutting-edge technologies are implemented to push the resid conversion to maximum leading to naphtha (light & heavy) or directly to raw olefins.

CTC complexes are made of three blocks : the conversion one, the aromatics one referring to heavy naphtha processing and the olefins one for light naphtha and light ends processing.

A holistic view, achieved through a client-oriented multi-criteria analysis, is essential to ensure a viable CTC project implementation since each CTC project is unique.

You are proposed to discover how to take up the challenge of ultimate conversion leading to the highly coveted aromatics and olefins. Of course, Axens’ recommended pathways are customized to match your project specificities and Axens supports you at each phase of your project.

The structure of a CTC complex is organized around the two key routes :

Axens supports clients throughout the entire unit life cycle, from feasibility study up to unit start-up and follow-up. As the CTC projects involve high-performance technologies, it is of utmost importance to benefit from the whole range of solutions.

Capable to reach high conversion levels from all type of residues, the H-Oil®, ebullated-bed based process technology, targeting distillates production, has its rightful place within the CTC complex.

This unique breakthrough high-severity fluid catalytic cracking technology has the ability to convert residue fractions specifically into unmatched levels of light olefins.

At the interface between the refining and the petrochemicals world where the CTC complex stands, the Aromatics block is designed to synthesize base petrochemical products BTX (Benzene – Toluene – Xylenes). Nylon is manufactured from benzene and polyurethane from toluene. Among the three xylenes isomers, paraxylene is by far the most used one.

As a high performance fixed-bed atmospheric and vacuum residue hydrotreating technology, Hyvahl™ plays a key role in the preparation of the HS-FCC™ feed, allowing an increased production of propylene, which is essential in the CTC context.