Impulse® Series now offers a comprehensive range of hydrotreating catalysts with over 100 commercial references, a testimonial of clients’ trust in Axens’ expertise since its launch in 2013. The series covers all hydrotreating needs of the refinery from middle distillates and VGO hydrotreating to hydrocracking pretreatment. In addition, Axens’ Impulse® associated services can provide refiners with technical advices and assistance as well as drafting plans for hydrotreating and hydroprocessing needs.

To this regard, our client located in Australia selected the Impulse® HR 1246 CoMo catalyst as a way to improve both margins and production efficiency. This selection was made after they conducted pilot plant tests. Drawing on its intrinsic high activity, this catalyst reference was then blended with a regenerated HR 626 standard CoMo catalyst, thus enabling a sub-10-wppm sulfur diesel product while reducing the overall cost-to-fill.

When discussing hydrotreating catalyst performance, two criteria set up the standards: activity and stability. For a given application, refiners want to reach a high activity while preserving the stability. The Impulse® catalyst technology was engineered to help them achieve both objectives.

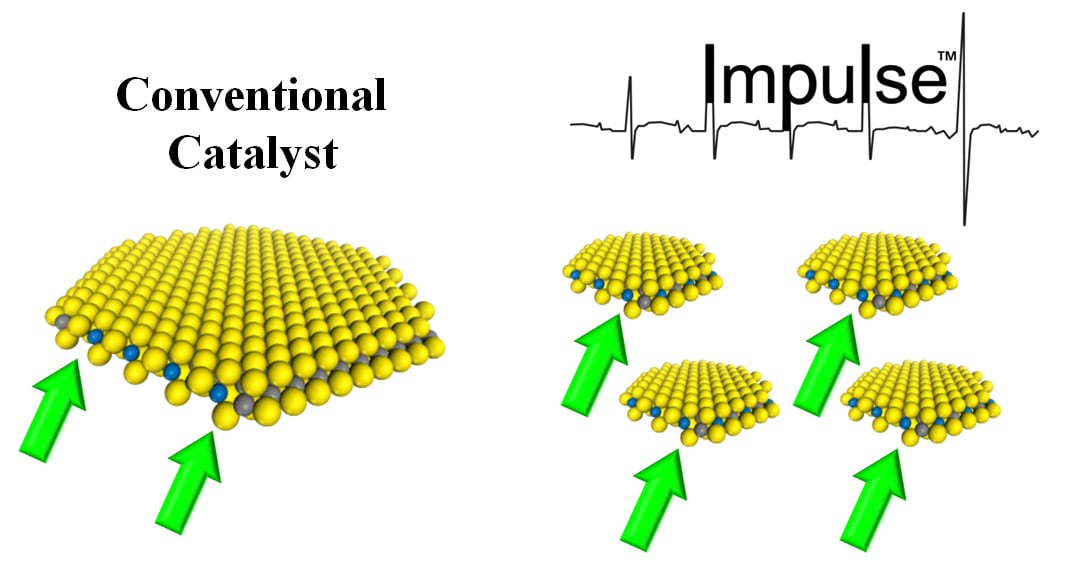

Above is a schematic representation of the difference between a conventional hydrotreating catalyst and the Impulse® Series catalysts. For the latter, the size of the active MoS2 slabs deposited on the alumina carrier are smaller and yet with more accessible sites. This is made possible thanks to an improved metal dispersion while using the same quantity of metals. In addition, the number of the highly active sites (Co(Ni)/Mo atoms in MoS2 edges) are significantly higher.

These features altogether with improved carrier properties endow Impulse® catalysts series with a dramatic activity increase while maintaining an outstanding stability.