Dec 18 2017

2 min read

Advanced Process Control (APC) is a part of automation engineering. Nowadays, automation engineering plays an indispensable role in plant operation, helping refiners complete exact tasks (from simple tasks, such as starting a pump, to more complex tasks, such as the automated sequence for hydrogen dryer regeneration) with reduced human intervention.

To make a plant operable, the first automation layer is the Distributed Control System (DCS) ensuring basic process control. The first industrial control computer system was built 1959 at the Texaco Port Arthur refinery in Texas. APC is the second layer in the lead of DCS. Not only does APC take control of process operation, it also optimizes it.

Axens APC is a multivariable Model Predictive Control (MPC). MPC identifies interactions between process variables as well as the dynamic relationships (models) between them, and uses matrix-math based algorithms to simultaneously control and optimize multiple variables. MPC was deployed in the 1980s thanks to increasing computer capabilities.

As a process licensor and catalyst supplier, Axens has first-hand knowledge of the best strategies and approaches for MPC design. Besides, Axens APC benefits from the latest generation of MPC, called MVAC (Multivariable State Space Controller). This allows better and safer operation by increasing plant yields, suppressing product over-specification, extending catalyst performance and service life, reducing utility and logistics costs, saving energy and decreasing carbon dioxide emissions.

Finally, APC also changes refiners’ ways of operation by introducing more automation, thus reducing work complexity.

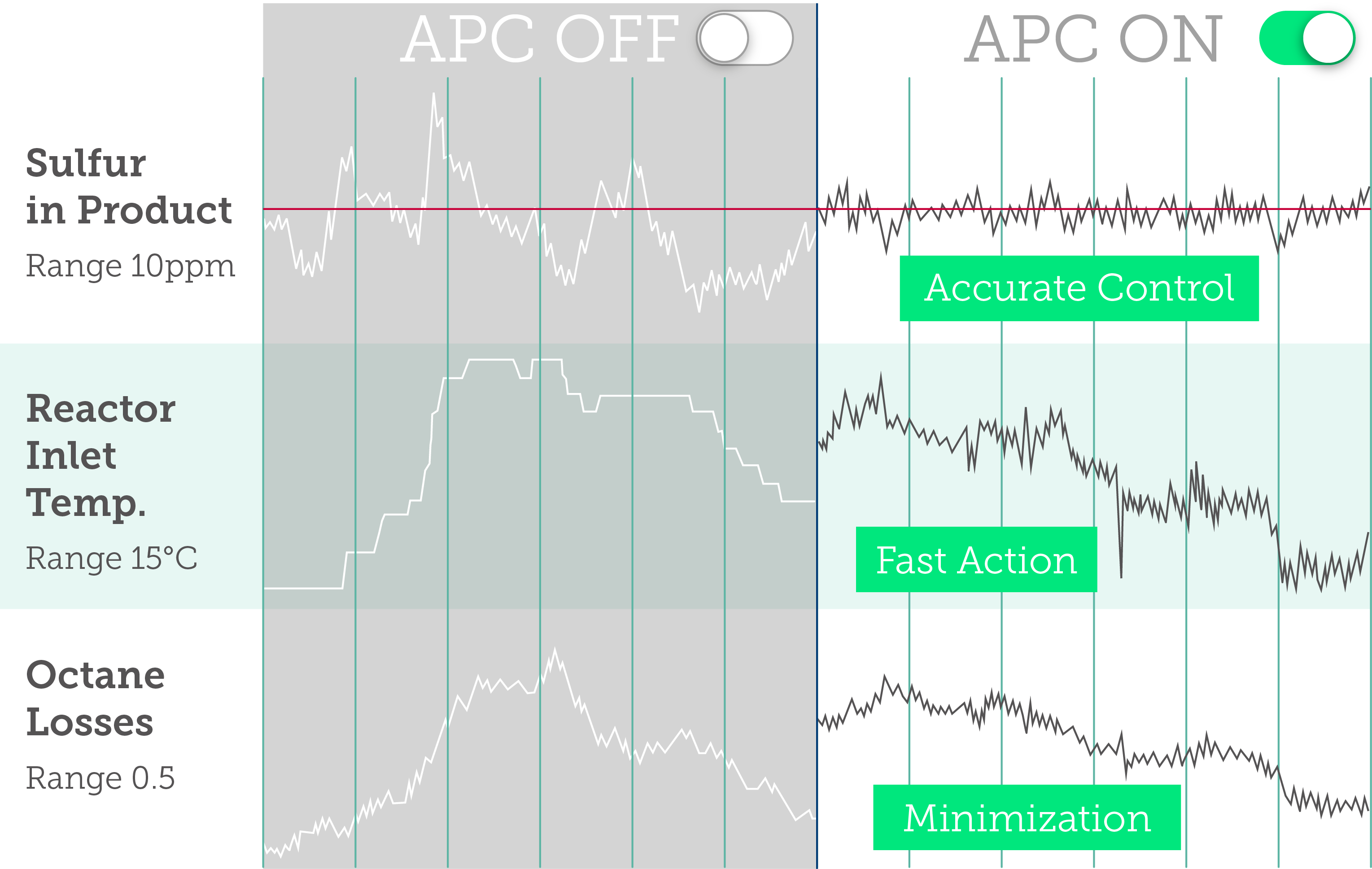

Benefits of APC generated by sulfur control in a gasoline hydrotreater. Example of 5 days of data on Prime-G+™ unit: APC keeps the Sulfur of the product on target and minimizes Octane Loss estimated on-line by Axens Inferential

In 2015 Axens designed an MPC for a 60,000 bbl/day FCC gasoline deep hydrodesulfurization unit for the SAMREF refinery, in Saudi Arabia. SAMREF is an equally owned joint venture between Saudi Arabian Oil Company (Saudi Aramco) and Mobil Yanbu Refining Company Inc. Total benefits for the operator are $0.34/barrel. That stands for $5.6 M/year.

Operation optimum is reached thanks to reducing gasoline product sulfur content give-away. APC leads to maximizing sulfur in gasoline product with constant compliance with the required specification (less than 20 ppm). This reduces HDS reaction section operation severity, consequently decreasing operating temperature, generating savings on octane loss, hydrogen consumption and energy consumption.

This project has been managed by Axens’ APC experts in close collaboration with SAMREF engineers. Only 4 months were necessary to build and commission the controller. Since then, the controller has been running perfectly and is achieving its optimization objective.