Jun 28 2019

2 min read

Selective hydrogenation is the technology of choice for the purification of highly valuable olefinic and aromatic streams produced by steam crackers and FCC units.

Axens Solutions’ latest generation of high performance selective hydrogenation catalysts is the result of a powerful R&D at both lab and pilot scales, state-of-the-art alumina carriers and cutting edge metal impregnation technologies.

High activity, excellent regenerability and highly competitive cost-to-fill are among the key advantages of this latest generation of selective hydrogenation catalysts. This latest generation of catalysts includes LD 485 (Pd-based), LD 465 (Pd-based), LD 541 (Ni-based), LD 551 (Ni-based), mainly for first stage pygas hydrogenation, and HR 606 (CoMo) for second stage pygas hydrogenation.

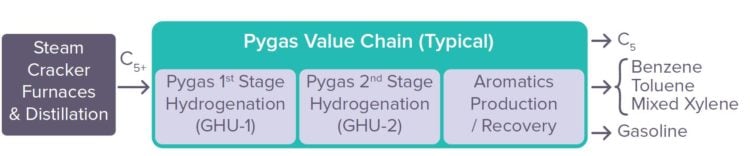

Typical pygas upgrading scheme

Axens Solutions’ received a very positive feedback from the market for these catalysts including head-to-head comparisons in industrial unit operation and several repeat orders. This success is confirmed by their rapidly growing reference lists.

The 100th Award of Axens Solutions’ latest generation of high performance selective hydrogenation catalysts is the result of a close collaboration with Galp, an important actor in the European refining market. In the context of a catalyst replacement in a Galp C4 selective hydrogenation unit using historically palladium-based catalysts, Axens Solutions recommended as a novel approach to load LD 541, a nickel-based catalyst, due to specificities in feedstock and operation of this particular unit.

This 100th award performs successfully in terms of butene-2 maximisation and butadiene conversion, and is also the first reference for LD 541 (multi-awarded in first stage pygas hydrogenation) in a C4 hydrogenation unit.